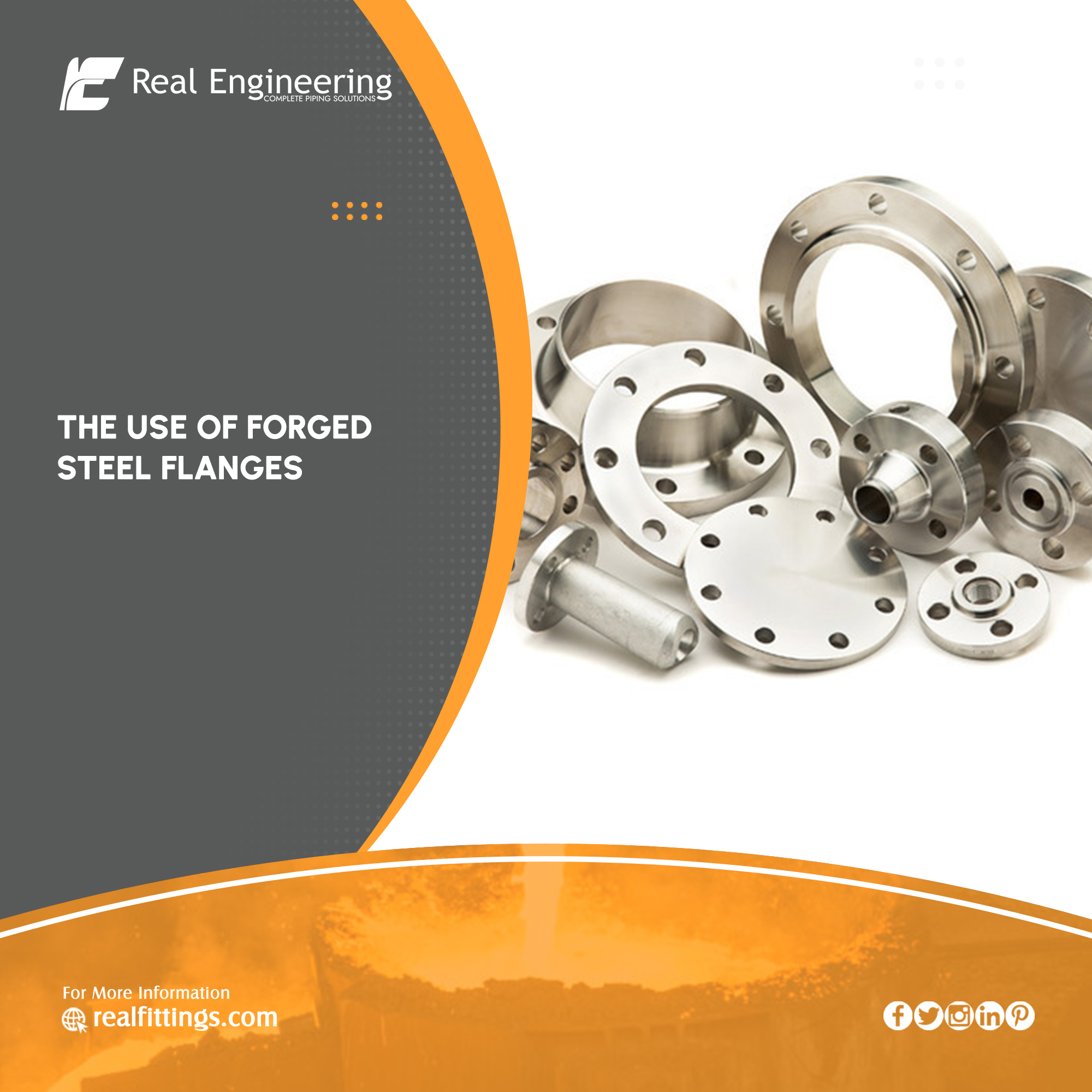

forged steel flanges supplier join 2 distinct machineries. They can be used as an extending to a framework to make it stronger. Manufacturing flanges have a wide range of applications, including trying to connect plates, pumps, pipelines, as well as constructions which require a transitional direct line of communication.

Type of Forged Flanges

There are many multiple kinds of stainless steel flanges. Each form meets its own requirements. Long showed that having flanges are connected to the pipe’s neck.

The way the above flange has been fastened ensures that depth is much like the aspects of the pipe to which it is attached. Such forged steel flanges supplier are typically used in elevated application areas.

Advantage

Certain aspects of shop fabrication will be eliminated by an FCI-forged link. A reinforced foam implementation eradicates the need for shed tears hole cutting, digging, floor plan, trying to form, and trying to tap.

The manufacturing of a nozzle neck eradicates a need to inspect tray necks, cut as well as bevel this same pipe, weld, form, as well as layout.

This same element manufacturing no longer requires welding and fitting the spacer to a pipe or forging a conical neck. This same Reinforced foam setup does not necessitate welding the bits to the ship’s shell or the nozzle’s chest.

Better Type of Quality Control

Safety checks for shop manufacturing, elements, and content track – and – trace have been reduced significantly. This allows Quality Control Investigators to focus their efforts on more pressing issues. Barrel defects also is drastically decreased.

Reduced Production Cost

The FCI has lowered the cost of manufacturing production. This includes material ordering, purchasing, fast tracking, quality assurance, safety checks, documentary evidence, running tests, the manufacturing timetable, and content ordering. All of this reduces manufacturing costs by saving money.

A Forged steel flanges suppliers is a tray device, typically round, that is related to the objectives of a pipe, going to fit, valve, and perhaps other artifact to enable pipe network removal process.

Forged flanges are used to connect cylinders, injectors, pumps, as well as other gadgets in a piping system.

Forged flanges combine two distinct segments of machines and equipment. They ought to be a frame connection to make the entity better. Industrial flanges are used to communicate sheets, pumps, pipelines, and structures that require a transitional contact point.

Stainless steel flaps come in a variety of shapes and sizes. Every form meets its own requirements. The welded neck’s huge flanges are held in place to the tubing’s base.

The way this flange is fastened ensures that the radius is the same as the pipe size to which it is connected. These flanges are also frequently used in elevated application areas.

Flanges are typically welded to pipes or mounted to a threaded end of a shaft before being connected to enable bolt interaction. It is widely used in the production of basic components and restricted quantities of sections.

The free fashioning equipment includes a compressed air screwdriver, a vapour air percussion, and a hydraulic pump for making smaller and broad forgings.

Rapid achievement, quick operation, simple milling, and automation The die forging size is too large, the milling stipend is small, as well as fabric trying to forge is more suitable and will extend the lifespan of the pieces even further.