Pipe Fittings are plumbing substances that help the direction of float in Adjustments, including elbows and tees. Changes in the scale of the tubing, for example, reducers and elevating tees, are some of the basic things.

Link-of-kind additives, including couplings, and disrupt flows, including caps, are also the basic job of forged fittings manufacturers in India. In piping of kind kinds of pipe becoming are used.

The Manufacturing Process Of Pipe Fitting

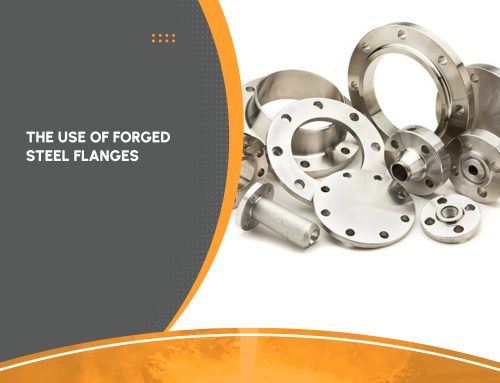

Forged pipe fittings are created in compliance with the requirements of ASME and are used to hyperlink pipes and pipelines for the nominal bore schedules. Forged Iron Pipe Fittings are available as becoming of the socket weld pipe or threaded pipe.

Forged fittings are built of A105 nickel or chrome steel alloy, and such fittings are more potent and thicker and are constructed for heavy business use.

Each casting becoming is completely marked with wished identity, and engraving markings do it at the collar portion. The most important goal is to preserve customers in consolation even as figuring out the specification and ensuring that the gadget runs smoothly.

The identity of A105 used by forged fittings manufacturers in India should no longer be marked due to the fact that carbon metallic fabric is grouped beneath trendy fabric grade. The magnificence stress 3000 and 6000 might be categorized as 3M or 6M. Here M stands for 1000.

3M way 3000 lbs becoming, and it is able to resist as much as 3000 PSI or 206 Bars. Other styles of fabric like SS316 want to be simply stamped on the correct body.

Forged Pipe Fitting Casting Work

Forged metallic fittings are pipe fittings that can be constructed from carbon metallic material, and it is a technique that creates robust fitting. The carbon metallic receives heated to a molten temperature, after which it’s far positioned within the dies.

The heated metallic is then machined into cast metallic fittings by forged fittings manufacturers in India. High-power cast metallic fittings from India are long-lasting and resilient to weather factors. These forms of fittings produce a brilliant seal on your piping system.

Forged fittings, which might be cast socket weld pipe fittings and cast threaded pipe fittings, are crafted from stable blocks of metallic. It might be machined to provide the last vital form in the tolerances described via way of means of the relevant standards.

Buttweld fittings, on the alternative hand, are made via way of means of cutting, bending, and shaping seamless or welded metallic pipes.

When a strong and long-lasting connection is needed, socket weld pipe fittings are the manner to go. Despite its reliability, socket weld fittings want a variety of time to put in a pipe system because of the heavy workload resulting from welding operations on small parts.

Conclusion

Forged flanges are used in different industries, and there is a particular type of manufacturing process for these flanges. This article is an extensive guide for these flanges and talks exactly about how these flanges are made.

Also Read:

Tips for Choosing the Right Forged Flanges Manufacturer